A Stealthy HF Coat Hanger Antenna

Update (Summer 2004): Hurricane Gaston decided I didn't really need this antenna and snapped off the supporting branch at the top and destroyed the antenna. I'm glad though that that's the only damage we suffered. Others were not so fortunate.

A Stealthy HF Coat Hanger Antenna

No, this is not about some cute antenna that's about the size of an oatmeal box and runs at 100% efficiency from 160 all the way up to 10 meters (and 6 meters if you leave the oats). In fact, there's nothing new on this page. It's just about a very common HF antenna that I recently built.

First an eyes check. Do you see an antenna in this picture?

You mean the leaves are in the way and the picture is taken from too far away to see it? Well, here's a close up with no leaves on the tree.

Of course now you can see it because you know what to look for and I told you that there is one. (in fact there are two antennas in the picture, there's also a 2 meter vertical in the tree on the left) You're looking at a 110 foot inverted-V, fed with homebrew ladder line. The apex is at 60 feet. The pictures were taken from my driveway. I ask folks who come to visit if they can spot it, but I always end up pointing it out to them. I never meant the antenna to be stealthy, it just so happens to turn out that way.

This is what the antenna looks like when you're right underneath it:

The antenna is made from a $15, 500 ft roll of black #14 insulated stranded wire, about 120 small black wire ties, and maybe 30 or so large black wire ties. You need black wire ties because they are UV resistant, and they will cost you just a few dollars at a hamfest, flea market or hardware store. If you can't find black ones, just go with the white ones. Too much worrying about the best possible materials will not get you on the air any quicker. :)

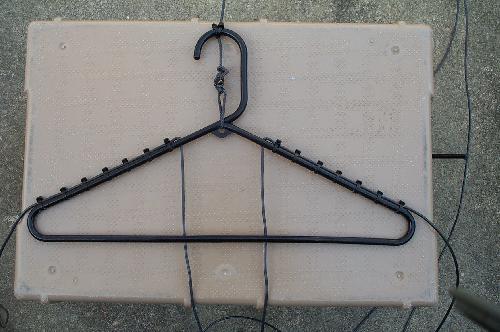

12 black plastic coat hangers were used to make the spreaders and center insulator from. The coat hangers will set you back another 2 bucks. So if you have to buy all the materials new, the antenna would cost you about $25, tops.

started out by making a whole bunch of spreaders from the coat hangers. I cut the coat hangers in straight pieces of 3.5 inches long. Each coat hanger is good for about 7 or 8 spreaders. I drilled a hole on each side of the spreader that would be large enough for small wire tie. I also put a little groove perpendicular to the holes in the spreader on each end of the spreader. This helps to keep the wire on the ends of the spreader.

The antenna and feed line contain no splices. So one leg of the antenna and one side of the open wire (ladder line) is made from one piece of wire. I cut two 125 foot long wires from the roll. Then I measured 65 feet on each wire for one leg of the inverted V and marked it with tape. The remaining 60 feet were used to build the open wire line.

Next I prepared the center insulator. Rather than cutting some nifty center insulator from some piece of plastic, I decided it was too hot for so much work, and used a whole coat hanger instead. :)

Each leg of the inverted V is tied down with the large wire ties on the top of the coat hanger. I made a small groove with the edge of a flat file in the coat hanger that helps keeping the wire in place. Then the wire drops down through holes in the coat hanger where the wire starts its life as open wire feedline.

Here's a detail shot of the center insulator which shows how the wire is fastened to the insulator:

The next detail picture shows how the rope is attached to the center insulator:

After the center insulator was done I started building the open wire line from the two 60 foot wires that come out of the bottom of the center insulator. Every 18 inches I put one spreader. The 18 inches between the spreaders is rather arbitrary. The wire is tied to the spreader with a small wire tie, and then I put a drop of Krazy glue between the wire and the spreader to make sure the spreader doesn't slide on the wire. The glue is not really necessary, but is an extra insurance. Once the spreader is put on the wires it will look like this:

To get the antenna in the tree, I used a slingshot to shoot a fishing line over the tree. Don't worry too much getting it over the "right" branch. I've tried that for a while with very little luck. Once I had the fishing line over the tree I pulled the support rope over the tree with the fishing line. Then I attached the center insulator to the support rope and pulled it up in the tree.

Instead of just tying the rope off on the trunk of the tree, I use a pulley and weight system to give the antenna and rope some freedom to move around in the wind:

As a weight I use 3 peanut butter jars filled with rocks. The jars are tied together with some #14 solid insulated house wire and duct tape. The reason that I used 3 jars instead of one larger is, that I used to have a just a simple wire in the tree that required only one jar. Then I added more wire to it and a second jar was necessary. To keep the inverted V up in the air I needed a third jar. Since I go faster through this brand of peanut butter than anything else that comes in a large jar, it may take a while before I can replace the three jars with one large one. :)

Each end of the inverted V is tied off on a small insulator made from a short piece of PVC pipe. On the other side of the insulator I tied a rope that goes to a support structure. One side of the antenna sneaks through an opening between the branches of other trees to a weight a pulley system. Here you can see how this leg of the antenna sneaks through the trees. The insulator is on the right.

As you can see the wire was too long for the space I had to put the antenna in, so I coiled the remaining wire (8 feet or so) up and attached it to the insulator.

The weight system on this side of the antenna is similar to that of the center support:

This weight system has saved me a lot of grief. At first I just had the rope tied off on the trunk of the tree. However, every time we got a good bit of wind the wire got caught in the branches from the trees it goes through. This happens because when the center of the antenna moves towards this end, the wire would drop onto the branches where it can easily get tangled. The weight system keeps the wire nicely under a small amount of tension that keeps the wire away from the branches. Ever since I put this weight system in place I never had the wires caught again in the branches.

The other side of the antenna goes to a weight system attached to the eve of the roof:

This picture gives you a better view of the insulator. On this end I used a marine type pulley just to see how well it would work. I've noticed that the clothesline pulleys work better for this small diameter rope, than the marine type pulley. Even though the marine type pulley runs freely, the rope just slides through it rather than that it causes the wheel to rotate. I guess there's not enough friction. I don't have this problem with the other pulleys.

The weight is not shown in this picture. The weight actually travels freely up and down in a bush. I've tried making pictures of it, but you simply can't see it.

I've tied the open wire off onto the eve of the roof using an electric fence insulator.

From there it goes to the window below where it enters the shack.

I cut a wooden board a while ago to fit in the window so that I can drill as many holes for cables as I want without doing too much damage. :) I use a wooden stick as a standoff that allowed me to also create a drip loop in the open wire feed line before it enters the shack. And yep, it works:

Once the open wire feedline gets into the shack, it goes straight to the tuner.

I can tune this antenna from 160 to 10 meters. On 160 I can also short the feedline and tune the antenna system as a T wire antenna against ground, but it seems to make very little, if any, difference.

Because I don't cut the support ropes to length once the antenna is up, I can take it down and put it back up within minutes. If a bad storm approaches or if I want to inspect the antenna, I can take it down within 5 minutes by simply taking the weights off. It may take about another 5 minutes or so to get it back up. I mark the rope with a piece of duct tape so I know where the weights go.

The best thing I like about this antenna is that I can be QRV on all HF bands with only one antenna and one feedline. The fact that it is rather inconspicuous is a nice bonus. This antenna system has been through several storms and stayed up nicely. The only thing I may have to do is pull the center support back up a bit after strong winds have had their fun with the antenna